We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

IOSH Managing Safely Course is a big umbrella under which IOSH Managing Safely Risk Assessment is an integral part. This is designed to equip managers and supervisors with essential knowledge and tools to handle Health and Safety responsibilities effectively. Moreover, this part majorly focuses on the systematic process of identifying potential hazards.

It evaluates the risks associated with those hazards and implement appropriate measures to control or eliminate them. It also aims to create a safety-conscious culture within organisations, which ensures that it not only compliance with legal requirements but also promote a proactive approach to preventing accidents and ill health in the workplace. Want to learn more how you can manage risks efficiently? Read this blog further to learn everything about IOSH Managing Safely Risk Assessment!

Table of Contents

1) What is IOSH Managing Safely Risk Assessment?

2) Stages of IOSH Managing Safely Risk Assessment

a) Basic assessment details

b) What is a Hazard?

c) Who might be harmed?

d) How might people be harmed?

e) Existing risk control measures

f) Risk Rating

g) Additional controls

h) New risk rating

i) Action/Monitored by whom?

j) Action/Monitored by when?

k) Closing details

3) Example of an IOSH Risk Assessment Form

4) Conclusion

What is IOSH Managing Safely Risk Assessment

Administered by the Institution of Occupational Safety and Health (IOSH), Managing Safely is the authority course on managing Health and Safety at workplace. It involves assessing risk that assists organisations in identifying, evaluating, and controlling workplace dangers to prevent accidents and injuries. Thus, this course is named: IOSH Managing Safely Risk Assessment.

IOSH Risk Assessment provides managers and supervisors with the skills and knowledge they need to identify possible hazards, assess the risks and take action to eliminate or control them. It is a practical project part of the IOSH Managing Safely course. We will discuss a practical Risk Assessment where you need to identify hazards and safety risks. You will learn how to identify four hazards at your workplace and list the following things:

1) Who might get harmed and how?

2) What are the control measures that are already in place?

3) Current risk rating

4) What are some of the additional controls that can be added?

5) How do the new controls change the risk rating?

6) When and who will implement these new controls?

Stages of IOSH Managing Safely Risk Assessment

There are multiple stages to complete the IOSH Risk Assessment. Let's break down each stage and help you have a clear understanding of each stage:

Basic assessment details

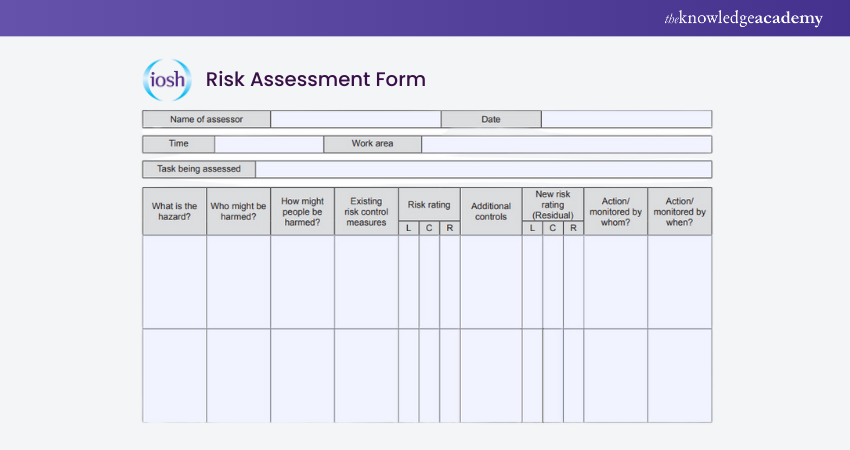

This is given at the top of the IOSH Risk Assessment Form and contains all the basic details about the individual carrying out the assessment (assessor). Let’s look at each of the data that needs to be filled in:

a) Name of assessor: This refers to your name; not the IOSH Managing Safely examiner.

b) Date and time of the assessment

c) Work area: This refers to the area where you will carry out the assessment. It could be a warehouse, office or a workshop. Do not just mention the place vaguely. Describe the place in brief. For example, a workshop that is 700 square meters with 2 CNC machines (can also describe the number of people)

d) Task being assessed: Be specific about the situation that want to assess. For example, you are assessing the operator using a CNC machine and storing the finished product.

For the first stage, you need to plan out the work area and task being assessed before going into the assessment. Pick an area and situation where there are hazards that you can assess and control them. This section carries a total of one mark.

What is a Hazard?

Hazard is defined as something that has a potential to cause harm. You need to select four hazards that are not being controlled appropriately. Each hazard carries one mark.

Make sure that the hazard you are describing is not too vague. For example, instead of “tripping”, it should be “trip hazards because of trailing wires”. It is critical to understand that the hazard is not necessarily what directly causes harm. Taking the same example, “tripping” is not a hazard but “trailing wires” or “wet floor” is a hazard. Therefore, do not be too vague with the hazards you mention.

Understand the difference between hazards and risks, learn how to identify hazards with the IOSH Working Safely Training.

Who might be harmed?

After evaluating the hazards in the workplace, the assessor must determine who may be harmed by those hazards. This stage involves identifying the group of people who may be exposed to the hazards listed in the previous section.

The assessor must consider everyone who may be at the risk of each hazard. Employees, visitors, janitors, or any other group of people who may be at risk must be included. The assessor should evaluate whether certain groups are more vulnerable to the hazard than others.

For example, an unsuspecting visitor might be at a greater risk of tripping over trailing wires or slip on leaked oil. If the identified hazard is a piece of machinery at a factory, the assessor must consider whether employees may be harmed by utilising the machinery, as well as any visitors or contractors who may come into contact with the machinery.

How might people be harmed?

In this stage, assessor need to detail the nature of injury that the identified hazard could cause. There is no need to go into too much detail. Mentioning the nature of injury will suffice. In some cases, hazards can cause death which needs to be mentioned as well.

For example, falls from tripping over wire can cause bruise, concussion or broken bones. Blades on heavy equipment like standing drill or CNC can cause amputation or serious cuts. Do not exaggerate or undercut the severity of the injury caused by the identified hazard. Be precise about it.

Existing risk control measures

Next stage of the IOSH Managing safely Risk Assessment includes assessing the existing risk control measures that you can take. For example, a signage near the wet floor can warn people or having set of processes and training in place to avoid mishaps with the heavy machineries in a workshop. Whatever controls measures you have in place must be mentioned here.

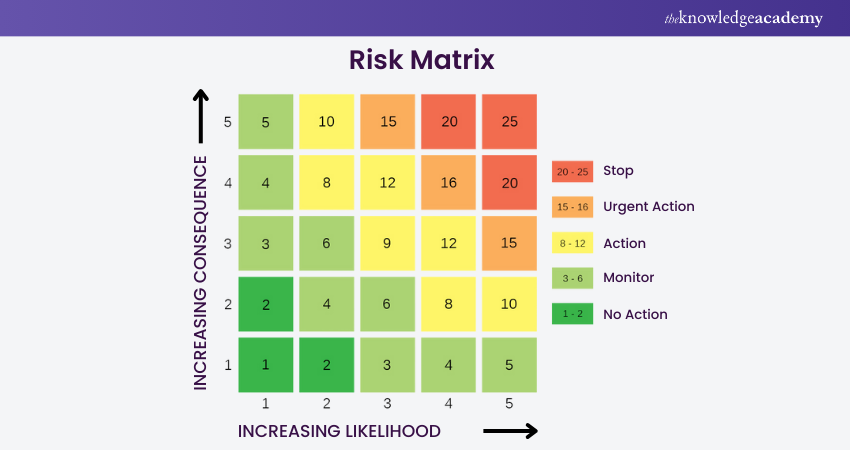

Risk rating

The Risk rating is used to rate the seriousness of the hazards. The goal of this matrix is to assist the assessor in prioritising the hazards and determining which ones must be handled first. The assessor must assign a risk rating to each hazard based on its likelihood and probable effects. A risk matrix can be used by the assessor to determine the risk rating for each hazard. Here's what a risk rating chart might look like:

The Risk matrix

The risk matrix combines the ‘likelihood’ and ‘consequence’ of each hazard to provide a risk rating. The hazard’s likelihood (denoted by ‘L’ on the assessment form) is assessed on a scale of 1 to 5, with 1 being unlikely and 5 being extremely likely. The hazard’s consequence (denoted by ‘C’ on the assessment form) is also assessed on a scale of 1 to 5, with 1 being minor and 5 being severe. The risk rating is calculated by multiplying the likelihood and consequence scores.

For example, if the hazard’s likelihood is 3 and the consequence is 4, the risk rating is 12 (3 x 4). The risk rating can be used to prioritise the threats and determine which hazards must be addressed first. The highest risk has a rating of 20-25 and calls for immediate action and stopping the associated activity. High-risk has a rating of 15-16 and calls for immediate action and stopping the activity if required.

Medium risk has a rating of 8-12 and calls for improvement in control measures under a strict timeline. Low-risk danger has a rating of 3-6 and calls for minor improvement in the next review or if there is a significant change. Any rating lower than this doesn’t call for any action, but it must be ensured that controls are maintained.

Additional controls

This stage involves identifying any extra control measures that can be taken to decrease the risks associated with the hazards identified. These new measures are known as additional controls.

The assessor must consider all possible control measures that can be implemented to reduce the risk rating associated with each hazard in this section. For example, replace a hazardous chemical with a less dangerous one or use machine guards to prevent access to moving parts in heavy equipment.

Management controls such as altering the way work is done to decrease the risk of harm, limiting exposure to a hazard, and supervision and safe systems of work can reduce risk rating. Another example can be the use of protective equipment like gloves, goggles, or respirators, for example, to protect against chemical exposure or airborne particles.

Once the additional control measures have been selected, they should be noted in the risk assessment form’s “Additional Controls” section. This part should include a description of the control measure in brief.

New risk rating

After implementing the additional control measures, the assessor should use the risk matrix to update the risk level associated with the hazard. If the added controls are effective, the new risk rating should be lower than the previous risk rating. If the control measures are ineffective or insufficient, the new risk rating may be maintained or even raised.

The assessor should check that the risk has been reduced to an acceptable level by the control mechanisms put in place. If the new risk rating is still high, the assessor should explore additional control measures to further reduce the risk rating.

However, the assessor needs to be careful with the consequence and likelihood rating. It is much easier to reduce the likelihood rating than the consequence rating. For example, placing machine guards can reduce the likelihood of getting cut by blades, but the consequence can still be amputation or severe cuts.

It is possible to reduce the consequence rating as well, but it is not always possible. For example, replacing a chemical with a less volatile or less dangerous chemical can do less harm, although such measures are not always practical.

Action/Monitored by whom?

In this stage, the assessor must mention who will be responsible for the implementation of the new control measures. For example, an operations or HR manager or a site supervisor can be mentioned in this section.

Action/Monitored by when?

In this stage, assessor need to mention the dates or deadlines by which the new measures must be implemented. Please note that hazards with high-risk ratings need to be addressed immediately while hazards with low or medium-risk ratings can be implemented with a more flexible deadline. It is also important to be practical about the dates you mention.

Closing details

The closing detail is the final section of the form and contains the ‘review date’ section. This refers to a set date on which identified hazards on the risk assessment are reviewed to check the effectiveness of new control measures.

Example of an IOSH Risk Assessment Form

Here are two IOSH Managing Safely Risk Assessment examples to give you an idea on how the form should be filled out. Let's have a quick look at each one of them:

|

Name of assessor |

John Hopkins |

Date |

27/04/2023 |

|||||

|

Time |

12:30 PM |

Work Area |

Workshop |

|||||

|

Task being assessed |

Working on standing drilling machine |

|||||||

|

What is the Hazard |

Who might be harmed? |

How people might be harmed? |

Existing risk control measures |

Risk Rating |

|

|||

|

L |

C |

R |

|

|||||

|

Oil leakage from the standing drill machine |

20 employees Janitor |

Concussion and broken bones due to slip and fall |

Notice to all employees to be careful around the machine |

4 |

4 |

16 |

|

|

|

Drill bit on the drilling machine |

4 employees (operators), visitors and janitor |

Cuts or amputation |

Safe work practiced by the operators and practice in place to not enter the area when drilling machine is in operation |

2 |

5 |

10 |

|

|

|

Additional controls |

New Risk Rating |

Action/ Monitored by whom? |

Action/ Monitored by when? |

||

|

L |

C |

R |

|||

|

Repairing or replacing the machine, adding a rubber mat around the machine |

2 |

3 |

6 |

Supervisor |

2/05/2023 |

|

Placing a machine guard and training on safe practices |

1 |

5 |

5 |

Supervisor |

7/05/2023 |

Conclusion

IOSH Managing Safely Risk Assessment might seem like a lot of work but with the help of this blog, you will be able to complete the assessment. Completing this course will give you a lot of confidence in the implementation of these safety practices at the workplace. This can significantly reduce workplace injuries, and monetary loss and avoid any potential lawsuits.

Learn how to assess and manage risks at the workplace with our IOSH Managing Safely Course – join today!

Frequently Asked Questions

The completion time for the IOSH Managing Safely Risk Assessment project varies depending on the course provider, but typically, you are given two weeks to a month after the end of the course to submit their assessment. This allows sufficient time to apply the knowledge learned and conduct a thorough Risk Assessment.

The pass mark for the IOSH Managing Safely Risk Assessment varies by the specific course and assessment criteria set by IOSH and the training providers. Generally, to pass, participants must achieve a score of 60% or above on the project and exam combined, demonstrating their understanding and ability to apply risk assessment principles.

The Knowledge Academy takes global learning to new heights, offering over 30,000 online courses across 490+ locations in 220 countries. This expansive reach ensures accessibility and convenience for learners worldwide.

Alongside our diverse Online Course Catalogue, encompassing 17 major categories, we go the extra mile by providing a plethora of free educational Online Resources like News updates, blogs, videos, webinars, and interview questions. Tailoring learning experiences further, professionals can maximise value with customisable Course Bundles of TKA.

The Knowledge Academy’s Knowledge Pass, a prepaid voucher, adds another layer of flexibility, allowing course bookings over a 12-month period. Join us on a journey where education knows no bounds.

Explore IOSH Training Courses with The Knowledge Academy, where more courses await, including IOSH Managing Safely Course, IOSH Working Safely Course and many more. Tailored for various skill levels, these courses offer in-depth insights into IOSH.

Dive into our Health & Safety blogs, a trove of resources covering Health and Safety topics. Whether you are a beginner or aiming to enhance your Risk Assessment skills, The Knowledge Academy's diverse courses and insightful blogs are your go-to source.

Upcoming Health & Safety Resources Batches & Dates

Date

IOSH Managing Safely Course

IOSH Managing Safely Course

Mon 13th May 2024

Mon 2nd Sep 2024

Mon 18th Nov 2024

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please