We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

Are you curious about the intricate web that connects the products you use every day to their origins? That’s the magic of Supply Chain Management (SCM); organisations can manage the flow of goods and services from start to end efficiently. But first, it is important for businesses to understand What is Supply Chain Management to bring growth to their business. Read this blog to gain an in-depth understanding of What is Supply Chain Management. Also, explore its importance, key components, challenges.

Table of Contents

1) Understanding What is Supply Chain Management

2) Key objectives of Supply Chain Management

3) Components of Supply Chain Management

4) Importance of Supply Chain Management

5) Supply Chain Management strategies

6) Challenges in Supply Chain Management

7) Conclusion

Understanding What is Supply Chain Management

The answer to "What is Supply Chain Management” is simple, yet, it is a complex practice in practicality. It is basically a strategic approach to managing the flow of goods, services, information, and finances from the raw material suppliers to the end consumers. It connects various branches within a business, making the transportation of products through the entire value chain easy.

Transform your Supply Chain with our Supply Chain Management Training- Join now!

Key objectives of Supply Chain Management

Let’s have a brief look at the main objectives of SCM and the impact it has on business operations:

Cost optimisation

One of the primary objectives of SCM is to optimise costs at every stage of the Supply Chain. By monitoring processes, reducing wastage, and improving resource allocation, businesses can achieve cost efficiencies. This leads to better profitability.

Efficient resource utilisation

SCM focuses on utilising resources like raw materials, manpower, and production capacity. By ensuring that resources are allocated optimally, companies can avoid excess inventory costs and improve overall productivity.

Meeting customer demands

Customers' expectations are constantly evolving, and SCM aims to meet these demands effectively. By syncing production and distribution with customer needs, businesses can enhance customer satisfaction and loyalty.

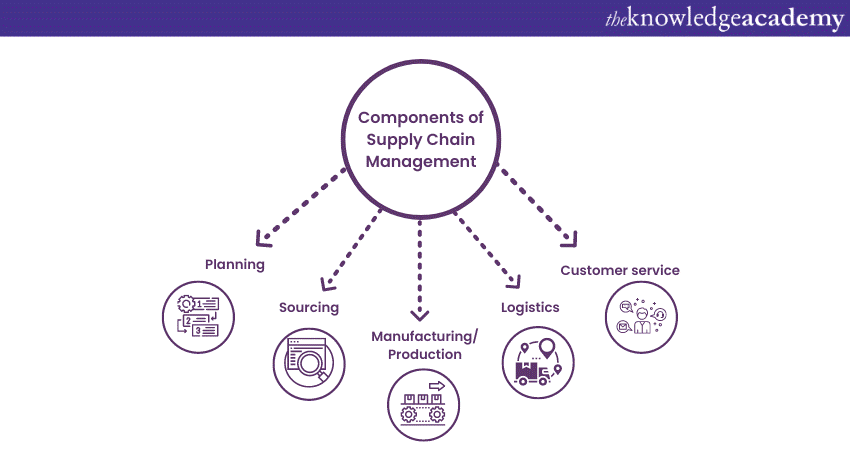

Components of Supply Chain Management

After understanding What is Supply Chain Management, it’s time to learn about its key components. SCM comprises several interconnected components that collectively ensure the smooth flow of services and products from suppliers to customers. Various components are listed below:

Planning

Planning is the fundamental element of SCM, comprising various activities that lay the groundwork for effective Supply Chain operations. Planning involves the following to make strategic decisions to improve the business:

a) Forecasting

b) Demand planning

c) Inventory management

Sourcing

Sourcing involves the identification and selection of suppliers who provide the necessary raw materials, components, or finished products. It also involves the following:

a) Identifying suppliers

b) Negotiating with them

c ) Management of supplier relationships

Manufacturing/Production

The manufacturing or production component is responsible for transforming raw materials into finished products. It is effectively carried out through operations management and process optimisation.

Logistics

Logistics plays a crucial role in physically moving goods from suppliers to manufacturers and from manufacturers to distributors or retailers. This includes transportation, warehousing and distribution.

Customer service

Customer service is a crucial aspect of SCM, focusing on delivering a positive experience to customers throughout the purchasing journey. The processes involved are as follows:

a) Processing of order

b) Delivery of the order

c) Post-sales support

These processes are carried out to maximise customer satisfaction.

Importance of Supply Chain Management

When executed properly, SCM brings numerous benefits to businesses, allowing them to grow in the dynamic marketplace. So, it's crucial to understand its importance. Here’s the importance of SCM:

Cost reduction and increased efficiency

Effective SCM allows businesses to identify areas of inefficiency and wastage within the Supply Chain. By optimising inventory levels and improving resource allocation, companies can reduce operating costs and enhance overall efficiency. A well-managed Supply Chain saves you time, reduces overhead expenses, and improves cost savings at every stage.

Enhanced customer satisfaction

Customer satisfaction is a crucial factor in maintaining a customer base and gaining a competitive advantage. SCM plays an important role in delivering a fruitful customer experience. It facilitates effective communication and collaboration among Supply Chain partners, enabling quick responses to changing customer needs and preferences.

Improved inventory management

Optimising inventory levels is a balance that can significantly impact a company's financial status. A well-structured SCM system provides real-time visibility into inventory levels and demand patterns. This allows businesses to maintain minimum stock levels, reducing the risk of stockouts and avoiding excessive inventory carrying costs.

Better risk management and Supply Chain resilience

Effective SCM allows businesses to build resilience and implement risk management strategies. By diversifying suppliers, creating emergency plans, and establishing alternative distribution channels, companies can reduce potential turmoil. They can also maintain continuity even in challenging circumstances.

Enhance your skills in Logistics Management through our Logistics Management Training - Reserve your seat now!

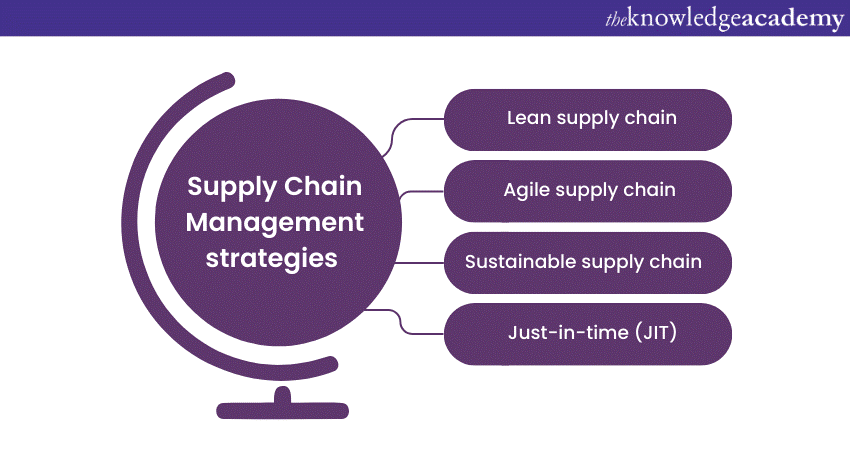

Supply Chain Management strategies

SCM strategies are designed to optimise processes, improve efficiency, and align with specific organisational goals. Here are a few strategies of SCM:

Lean Supply Chain

The Lean Supply Chain strategy focuses on eliminating waste and inefficiencies from the Supply Chain processes. It is inspired by the principles of Lean manufacturing and aims to reduce lead times and improve productivity.

By adopting Lean practices, businesses can identify and eliminate non-value-added activities, such as excess inventory, overproduction, and lengthy transportation routes. This strategy promotes continuous improvement and empowers employees to identify opportunities for process optimisation.

Agile Supply Chain

The Agile Supply Chain strategy stresses flexibility and responsiveness to ever evolving market conditions and customer demands. In dynamic and unpredictable environments, businesses must be adaptable and able to quickly adjust their Supply Chain operations.

Agile Supply Chain achieves this through real-time data analysis and close collaboration with Supply Chain partners. This allows companies to respond to trends, changes in demand, and acts of God.

Sustainable Supply Chain

The sustainable Supply Chain strategy connects environmental and ethical considerations into Supply Chain operations. Implementing sustainable methods can lead to cost savings by optimising resource usage and reducing energy consumption.

Sustainable Supply Chain Management is increasingly vital in today's world. It is because companies face growing pressure to address environmental concerns and promote social responsibility.

Just-in-time (JIT)

The JIT strategy maintains minimal inventory levels by receiving goods only when they are needed for production or delivery. This approach helps minimise inventory holding costs and the risk of excess inventory.

JIT relies on coordination with suppliers and ensures timely delivery to meet production targets. It requires strong communication with Supply Chain partners to prevent any altercations and collaborate well.

Challenges in Supply Chain Management

Despite the incredible advancements in technology and practices, Supply Chains still encounter various challenges that can disrupt operations. Discussed below are some common challenges faced by Supply Chains:

Demand variability and forecasting inaccuracies

Predicting customer demand accurately is a constant challenge for Supply Chain managers. Demand variability is majorly influenced by changing consumer preferences, market trends, and external factors. Thus, forecasting inaccuracies can result in excess inventory costs or missed sales opportunities.

To address this challenge, businesses must continuously improve forecasting models. It should also collaborate closely with sales and marketing teams to gain insights into customer demand patterns.

Supply Chain disruptions

Supply Chain disruptions occur due to natural disasters, geopolitical tensions, or unforeseen events that can have severe repercussions on operations. These disruptions can lead to delays in production, transportation, and delivery.

To mitigate such risks, companies must develop contingency measures. Risk management strategies such as diversifying their supplier base and allocating funds to address potential disruptions effectively.

Global Supply Chain complexities

As Supply Chains become increasingly globalised, they face complexities related to cross-border trade, customs regulations, and international logistics. Dealing with multiple languages, currencies, and legal systems can create communication barriers and delays in decision-making. Global Supply Chains also face several geopolitical tensions and trade policy changes that can impact the flow of goods.

Therefore, adopting advanced technologies, establishing strong partnerships with local stakeholders, and closely monitoring geopolitical developments can help manage global Supply Chain complexities.

Cybersecurity threats and data breaches

Supply Chains heavily depends on technology and data exchange, making them vulnerable to cybersecurity threats and data breaches. A cyber-attack can put all the operations to a standstill. It exposes sensitive information and leads to significant financial losses.

To safeguard against such threats, businesses must invest in advanced cybersecurity measures. It should also implement data encryption, conduct regular vulnerability checks, and provide cybersecurity training to employees.

Conclusion

We hope after reading this blog, you got an idea about What is Supply Chain Management. The primary importance of SCM lies in optimising operations and meeting customer demands. Businesses must invest in strategic SCM practices to get a competitive edge. By using effective measures and tackling challenges, businesses can achieve incredible success.

Unlock your facilitation potential – Sign up for our Facilitation Skills Training now!

Frequently Asked Questions

Upcoming Business Skills Resources Batches & Dates

Date

Supply Chain Management Training

Supply Chain Management Training

Fri 7th Jun 2024

Fri 6th Sep 2024

Fri 6th Dec 2024

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please