We may not have the course you’re looking for. If you enquire or give us a call on 01344203999 and speak to our training experts, we may still be able to help with your training requirements.

Training Outcomes Within Your Budget!

We ensure quality, budget-alignment, and timely delivery by our expert instructors.

In the face of uncertainties such as supply chain disruptions, businesses must prioritize effective Supply Chain Management to navigate challenges successfully. Understanding the components of supply chain management is crucial for businesses aiming to ensure resilience and continuity in their operations. However, implementing an efficient strategy for the management of the Supply Chain is not a piece of cake. That is where the different Types of Supply Chain Management Model comes in.

According to Statista, the US only suffered the most from supply chain disruptions, with an average annual cost of 180 million GBP. Therefore, by using different Supply Chain models, you can avoid such disruptions and expenses. Want to know how? Read this blog to learn about the six most important Types of Supply Chain Management models. Let’s dive in to learn more about it!

Table of Contents

1) Six different Types of Supply Chain Management

a) Continuous flow model

b) Fast chain model

c) Efficient chain model

d) Agile model

e) Custom-configured model

f) Flexible model

2) Conclusion

Six different Types of Supply Chain Management

Supply Chain Management plays a vigorous role in the success of modern businesses, enabling the efficient transfer of services and goods from the point of origin to the end consumer. Various Supply Chain Management Processes and models have been developed to optimise operations and maximise efficiency. Let's explore the six most important Types of Supply Chain Management models:

Continuous flow model

The continuous flow model focuses on maintaining a smooth and uninterrupted flow of products from the point of origin to the end consumer, minimising bottlenecks and delays. It leads to reduced inventory levels, cost savings, and improved customer satisfaction. Let's explore the benefits of the continuous flow model:

1) Reduced inventory: Avoiding excess inventory through continuous flow leads to cost savings in warehousing and carrying costs.

2) Faster response time: Real-time data and streamlined production enable rapid adjustments to changes in demand.

3) Cost efficiency: Eliminating inefficiencies results in producing more with fewer resources, optimising costs.

4) Enhanced quality control: Rigorous quality control throughout the production process improves overall product quality.

Implementing the continuous flow model requires careful planning, coordination, and investments in advanced technologies and automated systems. Collaborative relationships with suppliers and distributors are crucial for maintaining supply chain continuity.

The continuous flow model is particularly effective in industries with high-demand variability and rapidly changing market conditions. By adopting this approach, businesses can gain a competitive edge and achieve long-term success in today's fast-paced business environment.

Fast chain model

The fast chain model prioritises speed and responsiveness to meet customers' ever-changing demands promptly. It leverages technology, data analytics, and strategic partnerships for quick order fulfilment and delivery. Here are the benefits of the fast chain model:

1) Rapid order fulfilment: With efficient logistics and real-time tracking systems, companies can swiftly process and deliver orders to customers.

2) Agile inventory management: The fast chain model employs real-time data analysis to optimise inventory levels and ensure products are readily available.

3) Customer-centric approach: By focusing on meeting customer demands quickly, businesses can enhance customer satisfaction and loyalty.

4) Collaborative partnerships: Strategic collaborations with suppliers and delivery partners enable seamless and expedited supply chain operations.

Implementing the fast chain model requires a robust technological infrastructure and Agile business processes. Companies must invest in advanced Supply Chain Management software and collaborate closely with suppliers and delivery partners to ensure timely order fulfilment.

The fast chain model is especially crucial in industries where fast product delivery and response times are critical for remaining competitive in the market. By adopting this model, businesses can position themselves as market leaders and gain a significant advantage in meeting the needs of today's fast-paced consumers.

Join our renowned Train the Trainer course and gain the expertise you need to inspire and educate others effectively.

Efficient chain model

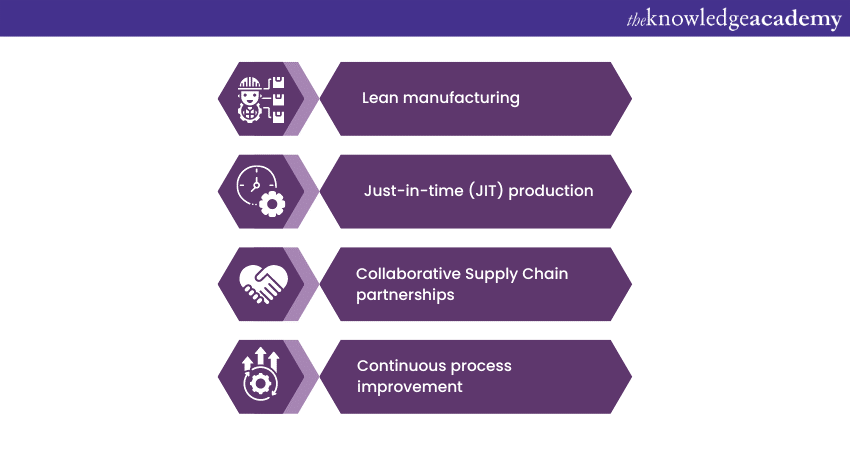

The efficient chain model emphasises cost-effectiveness and resource optimisation throughout the Supply Chain. By implementing Lean principles and streamlining processes, this model aims to reduce waste and enhance overall operational efficiency. Key characteristics and benefits of the efficient chain model include:

1) Lean manufacturing: The efficient chain model focuses on minimising excess inventory and non-value-added activities, leading to cost reductions and improved productivity.

2) Just-in-time (JIT) production: Adopting JIT principles ensures that production occurs only when there is actual demand. They reduce inventory carrying costs and minimises storage space requirements.

3) Collaborative supply chain partnerships: Close collaboration with suppliers and other stakeholders helps in improving demand forecasting accuracy and enhancing the overall efficiency of the supply chain.

4) Continuous process improvement: The efficient chain model encourages a culture of continuous improvement. It aims to identify and eliminate inefficiencies in the supply chain.

Implementing the efficient chain model requires a systematic approach to identifying areas for improvement, implementing lean practices, and optimising processes. Companies need to adopt innovative technologies and data analytics to drive informed decision-making and enhance supply chain visibility.

The efficient chain model is particularly beneficial for companies operating in cost-sensitive industries or facing fierce competition. By adopting this model, businesses can achieve cost savings, enhance operational efficiency, and create a competitive advantage in the market.

Agile model

The Agile model is a Supply Chain Management approach that prioritises adaptability and responsiveness in a rapidly changing business environment. This model allows companies to quickly adjust their plans and operations to meet changing customer demands and market dynamics. Here are the benefits of the Agile model:

1) Real-time data and analytics: The Agile model relies on real-time information and analytics to make informed decisions swiftly. This enables companies to stay updated on market trends and customer preferences.

2) Collaboration and communication: Close collaboration with suppliers, partners, and stakeholders is essential for the effective implementation of the Agile model. Clear and timely communication ensures seamless coordination throughout the supply chain.

3) Inventory optimisation: By closely monitoring demand and adjusting inventory levels accordingly, companies can avoid excess stock and reduce carrying costs.

4) Risk mitigation: The Agile model enables companies to identify potential risks and proactively implement contingency plans to mitigate disruptions.

Implementing the Agile model requires a flexible organisational structure and a culture that encourages innovation and adaptability. Technology plays a crucial role in providing real-time data, facilitating communication, and automating processes.

The Agile model is particularly effective in industries with short product lifecycles, unpredictable demand patterns, and rapidly changing consumer preferences. By adopting this model, businesses can enhance their ability to respond quickly to market changes. They can also capitalise on new opportunities and uphold a competitive edge in today's dynamic business landscape.

Master the art of Supply Chain Management with our Supply Chain Management Training – Sign up today!

Custom-configured model

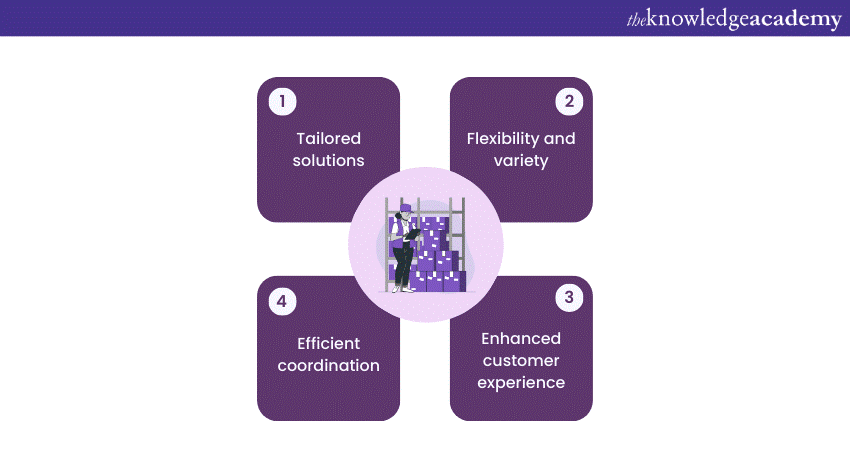

The custom-configured model is a Supply Chain Management approach that focuses on providing personalised products or services to meet individual customer requirements. This model is particularly prevalent in industries where customisation is a key differentiator, such as fashion, technology, and luxury goods. Let’s take a look at the benefits of the custom-configured model:

1) Tailored solutions: The custom-configured model allows companies to offer products or services that are uniquely tailored to each customer's preferences and specifications.

2) Flexibility and variety: Companies adopting this model must have a flexible Supply Chain capable of accommodating a wide variety of product configurations and options.

3) Enhanced customer experience: By providing personalised solutions, companies can boost the overall customer experience and build stronger brand loyalty.

4) Efficient coordination: Effective coordination between suppliers, manufacturers, and retailers is crucial to ensure smooth production and delivery of custom-configured products.

Implementing the custom-configured model requires advanced technology and efficient data management systems to handle the complexity of customisation. Additionally, companies need to collaborate closely with customers to understand their individual needs and preferences accurately.

The custom-configured model is a strategic choice for businesses seeking to differentiate themselves in competitive markets and cater to the growing demand for personalised products or services. By adopting this model, companies can gain a viable advantage and build long-lasting relationships with their customers.

Flexible model

The flexible Supply Chain Management model incorporates elements from various other models and allows companies to adapt their strategies based on specific situations. By combining aspects of continuous flow, fast chain, efficient chain, agile, and custom-configured models, businesses can tailor their approach to suit their changing needs. Let’s take a look at the key characteristics and benefits of the flexible model:

1) Adaptable strategies: The flexible model enables companies to adjust their supply chain strategies in response to changing market conditions, customer demands, or unforeseen disruptions.

2) Address risks: By having a flexible supply chain, companies can proactively address potential risks and implement contingency plans to minimise the impact of disruptions.

3) Scalability: The flexible model allows companies to scale their businesses up or down quickly to meet fluctuating demand and optimise resource utilisation.

4) Customer-centric approach: By combining elements of the custom-configured model, companies can offer personalised solutions while maintaining operational efficiency.

Implementing the flexible model requires a dynamic and responsive organisational culture. Companies must invest in technologies that provide real-time data and analytics to support decision-making. Collaborative relationships with suppliers and partners are also essential to ensure smooth coordination and communication throughout the supply chain.

The flexible model is especially advantageous for companies operating in industries with volatile market conditions and rapidly changing customer preferences. By adopting this model, businesses can stay agile and resilient, positioning themselves for success in a dynamic and ever-evolving business landscape.

Unlock the power of logistics management with our Logistics Management Training – Sign up today!

Conclusion

We hope you read and understand the Types of Supply Chain Management Models. These models offer unique advantages for businesses. Choosing the right model can optimise operations, reduce costs, and enhance customer satisfaction in today's competitive market.

Level up your skills and embrace success with our Industry Training – Sign up today!

Frequently Asked Questions

Upcoming Business Skills Resources Batches & Dates

Date

Facilitation Skills Training

Facilitation Skills Training

Fri 2nd Aug 2024

Fri 18th Oct 2024

Fri 20th Dec 2024

Fri 17th Jan 2025

Fri 28th Mar 2025

Fri 23rd May 2025

Fri 27th Jun 2025

Fri 8th Aug 2025

Fri 17th Oct 2025

Top Rated Course

Top Rated Course

If you wish to make any changes to your course, please

If you wish to make any changes to your course, please