Get a custom course package

We may not have any package deals available including this course. If you enquire or give us a call on +44 1344 203999 and speak to our training experts, we should be able to help you with your requirements.

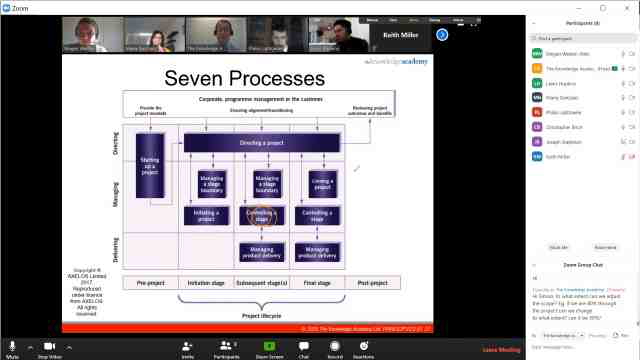

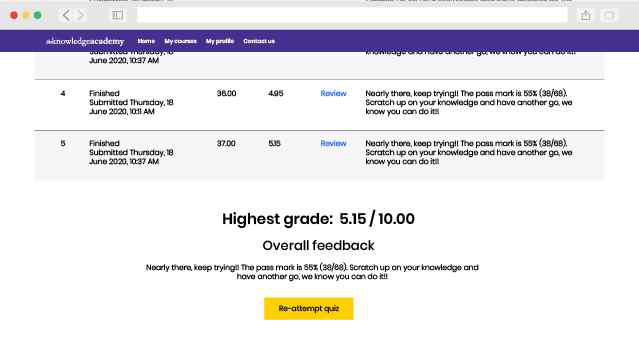

Module 1: Lean Processes

Module 2: Standardised Work

Module 3: Reducing Batch Size

Module 4: Poka-Yoke

Module 5: Total Productive Maintenance

Module 6: Time Management

Module 7: Value Stream Mapping

Module 8: Forming Pull Systems

Module 9: Lean Six Sigma

This Lean Processes and Tools Course is designed for professionals who are looking to strengthen their understanding of Lean methodologies and acquire practical skills in using Lean tools for process improvement. This training can be beneficial for the following professionals:

There are no formal prerequisites for this Lean Processes and Tools Course. However, a basic understanding of Lean and completing the Lean Awareness Training can be beneficial for the delegates.

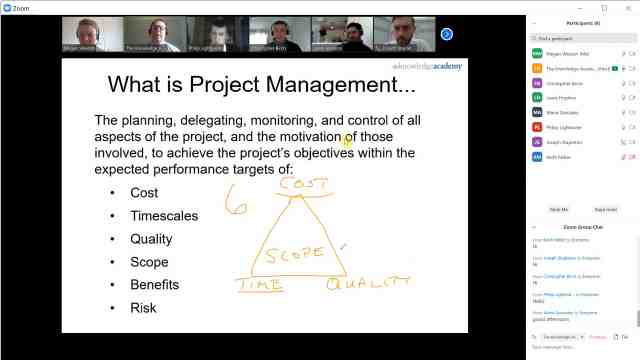

This Lean Processes and Tools Training is a comprehensive course that delves into advanced Lean methodologies, focusing on practical applications and tools to optimise organisational processes. It offers delegates an in-depth understanding of various Lean tools to streamline workflows, eliminate waste, and drive continuous improvement. This course provides a detailed overview of Lean tools and their relevance in enhancing operational efficiency.

Professionals aspiring to deepen their knowledge and expertise in Lean methodologies and tools should prioritise mastering the Lean Processes and Tools Training Course. Individuals involved in Process Improvement, Quality Management, Supply Chain Optimisation, and Operational Excellence across industries benefit significantly from advanced Lean knowledge. Mastery of Lean processes and tools enables professionals to implement sophisticated strategies for operational enhancements.

This 1-day Lean Training equips delegates with advanced Lean skills and practical insights to implement Lean methodologies effectively. Delegates will explore various Lean tools such as Value Stream Mapping, Kanban, 5S, and Kaizen. Through hands-on exercises and case studies, delegates will learn to apply these tools to identify inefficiencies, drive process improvements, and foster a culture of continuous improvement within their organisations.

Course Objectives

Upon completing this course, delegates will be equipped with advanced Lean skills to drive significant process improvements, streamline workflows, and foster a culture of continuous improvement.

Why choose us

Experience live, interactive learning from home with The Knowledge Academy's Online Instructor-led Lean Processes and Tools Training. Engage directly with expert instructors, mirroring the classroom schedule for a comprehensive learning journey. Enjoy the convenience of virtual learning without compromising on the quality of interaction.

Unlock your potential with The Knowledge Academy's Lean Processes and Tools Training, accessible anytime, anywhere on any device. Enjoy 90 days of online course access, extendable upon request, and benefit from the support of our expert trainers. Elevate your skills at your own pace with our Online Self-paced sessions.

Experience the most sought-after learning style with The Knowledge Academy's Lean Processes and Tools Training. Available in 490+ locations across 190+ countries, our hand-picked Classroom venues offer an invaluable human touch. Immerse yourself in a comprehensive, interactive experience with our expert-led Lean Processes and Tools Training sessions.

Boost your skills with our expert trainers, boasting 10+ years of real-world experience, ensuring an engaging and informative training experience

We only use the highest standard of learning facilities to make sure your experience is as comfortable and distraction-free as possible

Our Classroom courses with limited class sizes foster discussions and provide a personalised, interactive learning environment

Achieve certification without breaking the bank. Find a lower price elsewhere? We'll match it to guarantee you the best value

Streamline large-scale training requirements with The Knowledge Academy’s In-house/Onsite Lean Processes and Tools Training at your business premises. Experience expert-led classroom learning from the comfort of your workplace and engage professional development.

Leverage benefits offered from a certification that fits your unique business or project needs

Cut unnecessary costs and focus your entire budget on what really matters, the training.

Our Lean Processes and Tools Training offers a unique chance for your team to bond and engage in discussions, enriching the learning experience beyond traditional classroom settings

The course know-how will help you track and evaluate your employees' progression and performance with relative ease

You won't find better value in the marketplace. If you do find a lower price, we will beat it.

Flexible delivery methods are available depending on your learning style.

Resources are included for a comprehensive learning experience.

"Really good course and well organised. Trainer was great with a sense of humour - his experience allowed a free flowing course, structured to help you gain as much information & relevant experience whilst helping prepare you for the exam"

Joshua Davies, Thames Water

Back to course information

Back to course information

We may not have any package deals available including this course. If you enquire or give us a call on +44 1344 203999 and speak to our training experts, we should be able to help you with your requirements.

If you miss out, enquire to get yourself on the waiting list for the next day!

If you miss out, enquire to get yourself on the waiting list for the next day!

close

Press esc to close

close

Fill out your contact details below and our training experts will be in touch.

Back to Course Information